The Angle Lock

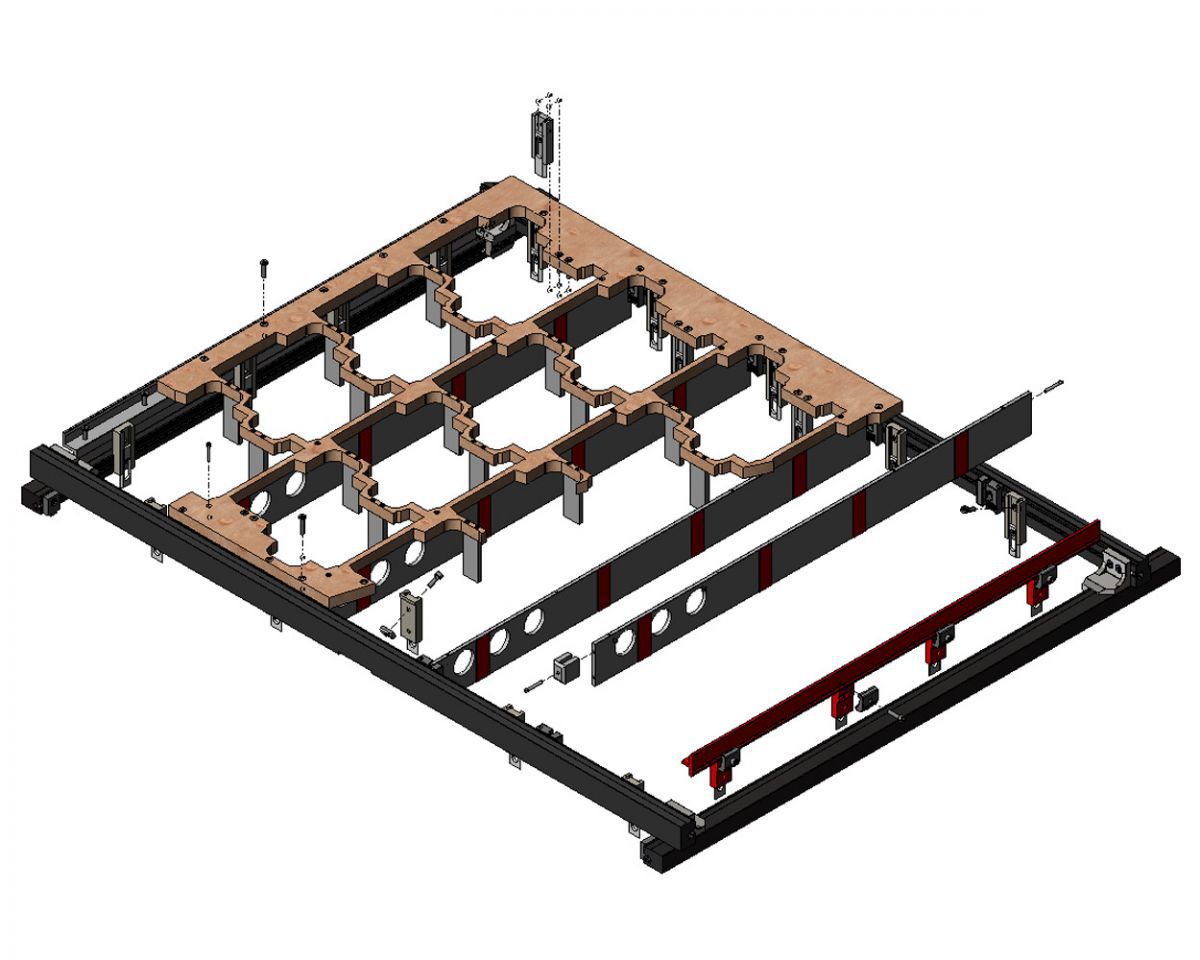

BSI has developed the Angle Lock blanking system with one simple goal: to be the best system available anywhere for building blanking tools. The system consists of tool design software, components, and accessories that constitute a fully integrated blanking tool fabrication system. Angle Lock blanking tools are extremely precise, rigid tools that typically permit a blanking station equipped machine to out-perform and out-produce machines running with tools made without the Angle Lock system. Customers have reported increases in machine operating speed of 10% to 20% as a direct result of using Angle Lock tools. The Bobst Group has endorsed Angle Lock by making it standard equipment in their lower blanking station for their entire range of SP Autoplaten presses.

Angle Lock Economics

Besides being fast to assemble and fast in operation, Angle Lock tools create additional savings by reducing press make-ready times. Furthermore, most Angle Lock components can be re-used after a tool is retired from service. All of these factors – tool precision, rigidity, ease of tool design and assembly, increased press operating speeds, and component reusability – result in significant real world savings that Angle Lock makes available to you today.

Product Engineering & Manufacturing

Angle Lock tools utilize a patented component location and connection scheme that ensures each tool component is mated to another with at least two precision machined surfaces. Fasteners are located at an angle to the connecting faces, resulting in an inherently square connection that is highly resistant to fasteners loosening during tool operation. Extensive product engineering and testing was used to assure that only the best materials, alloys, surface finishes and hardnesses are used in all components and accessories.

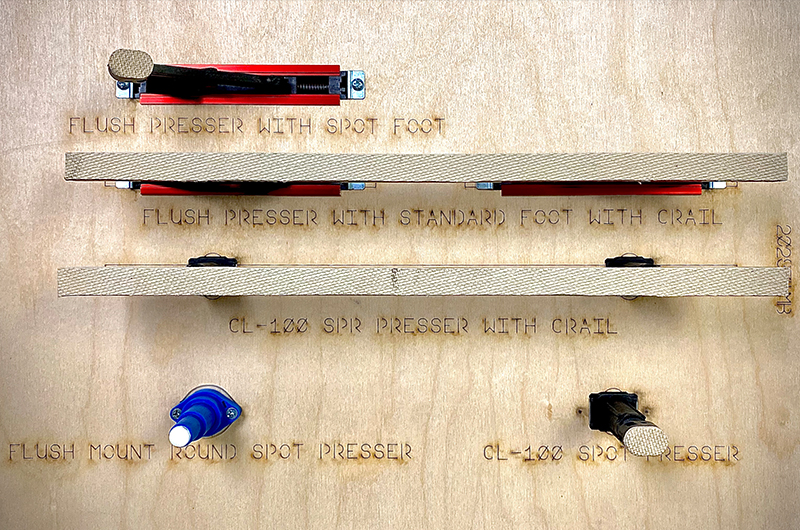

High Speed Pressers

Our high-speed line of pressers is designed and tested to operate in today’s high-speed diecutters. Capable of operating at speeds of 12,000 impressions per hour or more, it is not uncommon for these pressers to have a life expectancy beyond 50 million cycles. Insertion and removal of these pressers is quick and easy through the use of specially designed mounting clips.