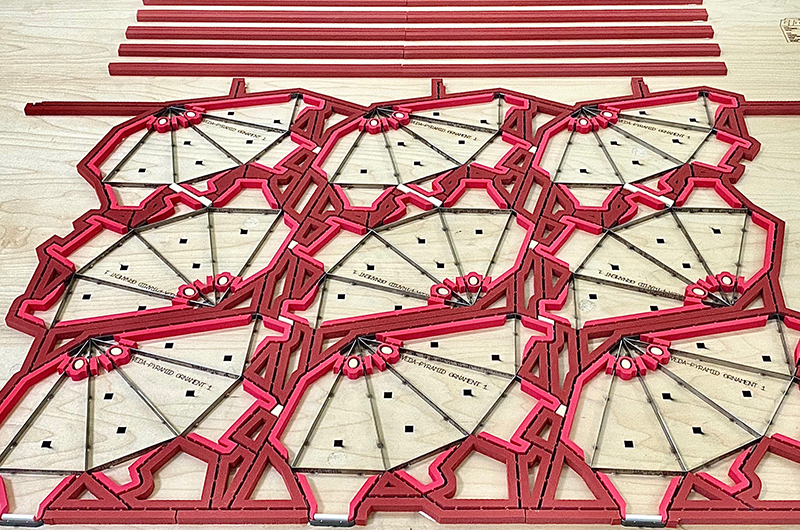

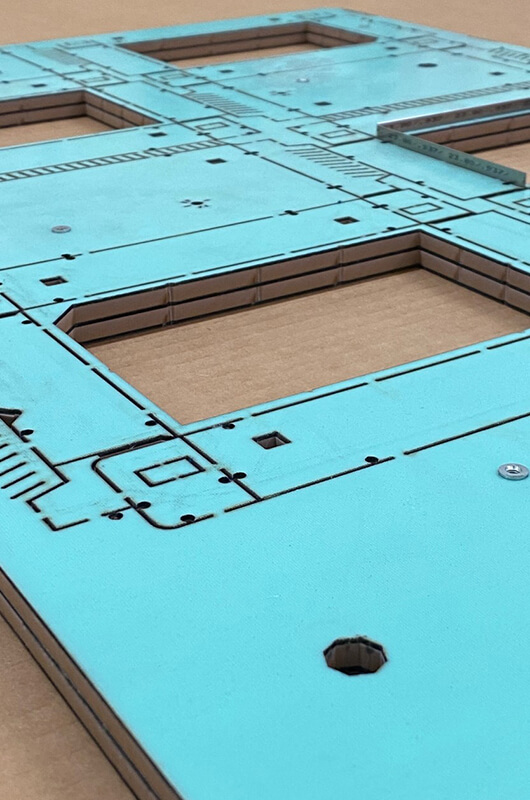

Cutting Dies

are the center of CTI’s business. The quality and passion we put into our die tooling create a performance/precision-based product for your cut and crease presses. We stand by the fact that our product will help you improve your make-ready times and increase your running speeds. All of our steel rule cutting dies are specified and manufactured to meet your requirements and needs.

We Provide

Our Promise: All CTI dies are measured on our Acu-Guage prior to shipment. These measurements are stored in our database and ensure that the die is within specification when shipped.

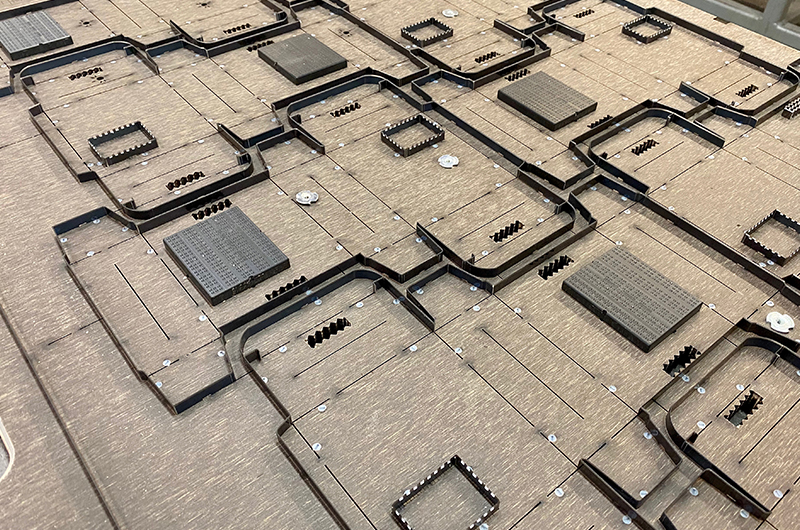

Die Board Bases

Maple

Birch

UV Coated Birch

Fused Birch

Rayform

UltraLite

Accu-Ply Die Board

Ejection Rubber

Precision water jet cut rubber has a direct impact on press make ready and run speed. Our standard is a combination of Bobst Blue Boost, Euro rubber and Durastrip. To minimize sheet nicks it is important to rubber die after it has been nicked. This practice will result in fewer nicks being required to deliver sheet.